Understanding Different Types of Vintage Gas Signs: Porcelain, Neon, and Metal

Vintage gas station signs are more than just nostalgic relics; they're tangible pieces of Americana, offering a fascinating glimpse into a bygone era of motoring and roadside culture. But not all vintage gas signs are created equal. The materials they’re made of profoundly impact their appearance, longevity, and, crucially, the restoration techniques required. This guide delves into the three primary types of vintage gas signs: porcelain, neon, and metal, outlining their characteristics and the unique challenges restorers face with each.

Porcelain Gas Signs: The Classic Look

Porcelain signs are arguably the most iconic and sought-after type of vintage gas sign. Their durability, vibrant colors, and distinctive appearance have cemented their place in collecting circles. But what exactly *is* porcelain, and how is it made into a sign?

Porcelain isn't the same as ceramic. Porcelain is a very hard, vitreous (glassy) type of ceramic. Vintage gas signs were typically made using a process called “enameling.” This involved applying layers of finely ground glass, mixed with pigments, onto a steel base. The layers are then fired at extremely high temperatures (often exceeding 1300°F/704°C) to fuse the enamel to the steel. The number of layers, the quality of the enamel mix, and the firing process all contribute to the final product's quality and longevity.

Common Characteristics of Vintage Porcelain Gas Signs:

- Durability: Porcelain is remarkably durable, resisting weathering and fading better than many other materials.

- Vibrant Colors: The enamels used provided a wide range of rich and vibrant colors.

- Glossy Finish: The fired enamel creates a distinctive glossy surface.

- "Orange Peel" Texture: Many older porcelain signs have a slight "orange peel" texture, a result of the firing process and the way the enamel settled.

Restoration Challenges with Porcelain Signs:

- Chips and Cracks: These are extremely common. Repairing them requires specialized skills and materials – often involving welding and applying matching enamel.

- Rust: Rust often forms behind the porcelain if the steel base has been compromised. This requires careful removal without damaging the enamel.

- Color Matching: Recreating the original enamel colors can be challenging.

- "Bubbles" and Imperfections: While sometimes considered character, these can be treated if desired, often requiring extensive work.

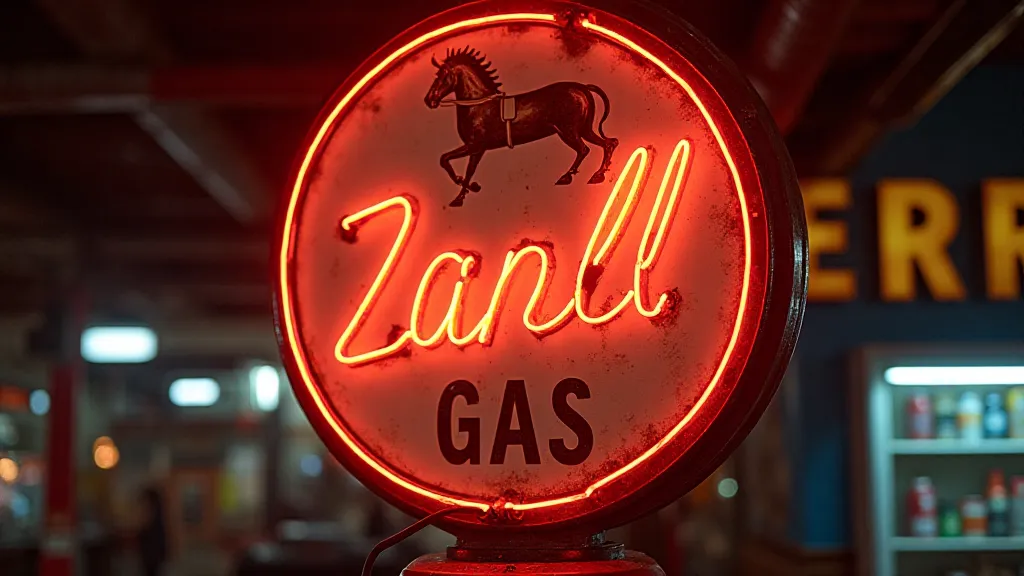

Neon Gas Signs: The Glowing Advertisement

Neon signs brought a new level of visual appeal to gas stations. The bright, eye-catching glow of neon was a powerful advertisement, especially during nighttime hours. While less common than porcelain signs, neon signs are increasingly prized by collectors due to their rarity and captivating appearance.

Understanding Neon Construction:

Neon signs aren't made entirely of neon. They consist of glass tubing filled with different gases – typically neon (which produces a red-orange glow) and other gases like argon, helium, and mercury – to create a spectrum of colors. Electrodes are sealed into the ends of the tubes, and a transformer provides the high voltage needed to excite the gas, causing it to glow. The tubes are often bent into elaborate shapes to form letters, logos, and decorative elements.

Common Characteristics of Vintage Neon Gas Signs:

- Unique Glow: The distinctive, vibrant glow of neon is the defining characteristic.

- Intricate Designs: Neon signs often feature complex and artistic designs.

- Glass Construction: The use of glass makes them fragile.

Restoration Challenges with Neon Signs:

- Broken Tubing: Damage to the glass tubes is the most common problem. Replacing or repairing them requires specialized skills and equipment.

- Transformer Issues: The transformers that power neon signs often fail. Replacing or repairing them can be complex.

- Gas Leaks: Leaks in the gas tubes diminish the glow and require careful repair.

- Blackening of Glass: Over time, the inside of the glass tubes can darken, reducing the brightness.

Metal Gas Signs: The More Affordable Option

Metal signs, often made of steel or tinplate, were a more affordable option for gas stations, especially during the Depression era. While less durable than porcelain, they still offer a piece of gas station history.

Types of Metal Signs:

- Tinplate Signs: These were often printed with colorful graphics using lithography.

- Steel Signs: These were generally more robust and often had painted lettering and graphics.

Common Characteristics of Vintage Metal Gas Signs:

- Lighter Weight: Compared to porcelain, metal signs are considerably lighter.

- Affordable: They were a more economical option for gas stations.

- Wide Range of Designs: Lithography allowed for a wide range of colorful designs.

Restoration Challenges with Metal Signs:

- Rust: Metal signs are highly susceptible to rust.

- Paint Loss: Paint often flakes off due to weathering and age.

- Dents and Bends: They are prone to damage from impacts.

- Fading: Colors fade significantly over time.

Restoring metal signs involves careful cleaning, rust removal, dent repair, and repainting. Matching the original colors and finish can be challenging.

Understanding the specific material and construction of a vintage gas sign is crucial for a successful restoration. Each type presents its own unique challenges, requiring specialized knowledge, tools, and techniques. Whether you're a seasoned restorer or a passionate collector, recognizing these differences will enhance your appreciation for these iconic pieces of Americana and ensure their preservation for generations to come.