Sealing & Protecting Your Restored Vintage Gas Signs

You’ve poured your heart and skill into restoring a beautiful vintage gas sign. The meticulous cleaning, the careful repainting (or touch-ups), the dedication to preserving its original character – it’s a significant accomplishment. But the work isn’t quite finished. Exposure to the elements – sun, rain, snow, and fluctuating temperatures – can quickly undo your efforts, causing fading, cracking, and deterioration. Properly sealing and protecting your restored gas sign is just as crucial as the restoration process itself. This guide will explore the best methods for safeguarding your vintage treasure, ensuring it remains a vibrant piece of history for years to come.

Understanding the Threats: Weathering and Degradation

Before diving into sealing techniques, it’s vital to understand the factors that contribute to weathering and degradation. Knowing the enemy is half the battle!

- UV Damage: Sunlight is a major culprit. UV rays break down pigments in the paint, leading to fading and discoloration.

- Moisture: Water intrusion can cause rust, paint bubbling, and ultimately, structural damage.

- Temperature Fluctuations: Constant expansion and contraction due to temperature changes can stress the paint and metal, leading to cracking and peeling.

- Pollution: Airborne pollutants can react with the surface of the sign, causing discoloration and dullness.

- Physical Abrasion: Windblown debris, accidental bumps, and general handling can all contribute to surface wear.

Choosing the Right Sealer: Options & Considerations

Selecting the appropriate sealer depends on the sign's material (metal, porcelain, etc.), its intended location (indoor display vs. outdoor exposure), and your desired aesthetic. Here’s a breakdown of common choices:

1. Clear Acrylic Sealers (Spray-On)

Acrylic sealers are a popular choice for their ease of application and relatively low cost. They form a clear, protective layer over the restored surface.

- Pros: Easy to apply with a spray can, readily available, offers good UV protection (look for UV-resistant formulas), relatively inexpensive.

- Cons: Can be prone to scratching and marring, may yellow slightly over time (some formulas), may require multiple coats for optimal protection.

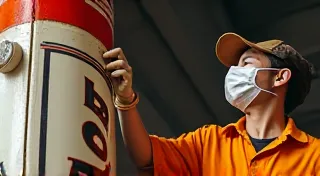

Application Tips: Apply in thin, even coats, allowing each coat to dry completely before applying the next. Use a respirator mask to avoid inhaling fumes. Multiple thin coats are better than one thick coat, which can lead to runs and drips.

2. Polyurethane Sealers

Polyurethane sealers offer superior durability and chemical resistance compared to acrylics. They’re a good choice for signs that will be exposed to harsh conditions.

- Pros: Excellent durability, good chemical resistance, provides a glossy finish (if desired), offers good UV protection.

- Cons: Can be more difficult to apply than acrylics (requires more skill to avoid brush marks), can be more expensive.

Application Tips: Thoroughly read and follow the manufacturer’s instructions. Use a high-quality brush or sprayer to ensure a smooth, even finish. Multiple thin coats are essential.

3. Epoxy Coatings

Epoxy coatings are the most durable option, providing exceptional protection against weathering and physical damage. They's are often used for signs that are heavily exposed to the elements.

- Pros: Superior durability, excellent chemical resistance, creates a very hard and glossy finish.

- Cons: Can be challenging to apply correctly (often requires professional expertise), can be the most expensive option.

Application Tips: Epoxy coatings typically involve a two-part mixing process. Precise measurements and thorough mixing are critical for proper curing. This is generally best left to experienced professionals.

4. Ceramic Coatings

Ceramic coatings are a newer option becoming increasingly popular. They create a super-hydrophobic surface, meaning water beads up and rolls off, taking dirt with it. They also offer excellent UV protection and scratch resistance.

- Pros: Excellent hydrophobicity, superior UV protection, high scratch resistance, long-lasting protection.

- Cons: More expensive than other options, application requires specialized tools and skills, may require professional installation.

Application Tips: Surface preparation is critical for ceramic coating application. The sign must be perfectly clean and free of any contaminants. Application typically involves multiple steps, including cleaning, masking, and applying the ceramic coating in thin, even coats.

Surface Preparation: The Key to Success

No matter which sealer you choose, proper surface preparation is absolutely crucial. A poorly prepared surface will compromise the sealer’s effectiveness and shorten its lifespan.

- Cleaning: Thoroughly clean the sign with a mild detergent and water to remove any dirt, grease, or loose particles.

- Sanding (if necessary): If the surface is rough or has imperfections, light sanding may be necessary to create a smooth base for the sealer.

- Primer (often recommended): Applying a primer can help the sealer adhere better to the surface and provide additional protection. Choose a primer that is compatible with both the sign's material and the chosen sealer.

Ongoing Maintenance and Reapplication

Even the best sealers aren’t permanent. Over time, they will break down due to exposure to the elements. Regular inspection and reapplication are necessary to maintain the sign's beauty and protect it from further damage.

- Regular Cleaning: Clean the sign periodically with a mild detergent and water to remove dirt and grime.

- Inspection: Inspect the sealer for cracks, chips, or fading.

- Reapplication: Reapply the sealer as needed, following the same surface preparation steps outlined above. The frequency of reapplication will depend on the sealer type, the severity of the exposure, and the overall condition of the sign.

Conclusion

Restoring a vintage gas sign is a labor of love. Protecting your investment is just as important as the restoration itself. By choosing the right sealer, following proper application techniques, and performing regular maintenance, you can ensure that your restored gas sign remains a vibrant piece of automotive history for generations to come.